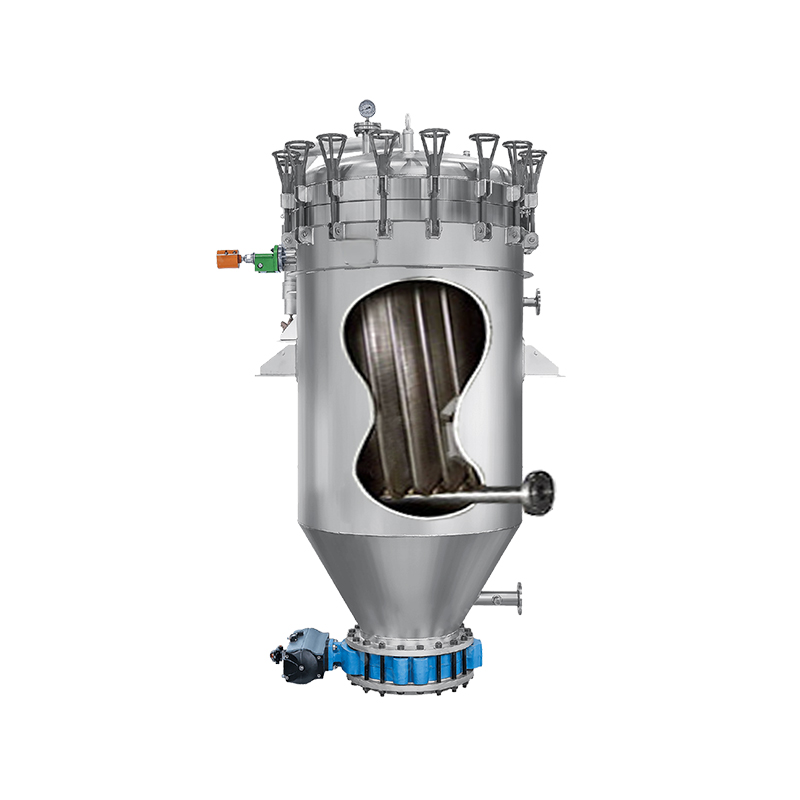

Cjrh series multifunctional three-in-one filter is a multi-functional solid-liquid separation equipment integrating filtration, washing and drying. lt is widely used in fine chemicals, pesticides, petroleum, food, printing and dyeing, medicine and other industries. In the production process, the user's influence on the surrounding environment or temperature on the product quality is relatively large, so our three-in-one equipment can meet the requirements. At the same time, our company produces aseptic filtration washing drying three in one filter. chemical grade washing, filtering and drying three in one filter, and filtering and washing two in one filter, The flexible configuration of the equipment ensures to meet the different application fields of customers.

In pharmaceutical production, fully enclosed production process has always been the best production mode pursued by pharmaceutical manufacturers. In this way, the pharmaceutical production process is not affected by external or artificial impurities and pollution, which can effectively ensure the quality of drugs, and the impact of production on the environment is the least. This production mode is in line with the development trend of clean production in the world. lt is difficult to strictly ensure the aseptic requirements in the process of loading or unloading between transport containers (boxes, drums or PE bags) and production equipment (dryers, mixers, subloaders, etc.). In order to meet the closed production process, our company has developed a filter, washing, and drying three in one unit, the production system can achieve complete automatic operation control.

The filter, washing and drying machine is used to complete the filtration, washing and drying process of crystal liquid in the whole multi-functional production process, including feeding, beating, filtering, washing, drying, discharging, online detection and other key steps, so as to prepare for the next mixing process of clean room production. The filter, washing and drying machine also has ClP and sip functions.

CJRH Multifunctional (Three-In-One) Filter

|

|

|

|

|

|

| Washing stage | Chemical Grade | Agitator | Detachable Chassis | Blowdown Valve | Sampling Valve |

Product Parameters

● Pharmaceutical intermediates and sterile APls

● Pharmaceuticals

● Fine chemical industry

● Printing and dyeing industry

● Chassis structure: fixed and dismounted

● Main materials: stainless steel 304, 316L, Hastelloy

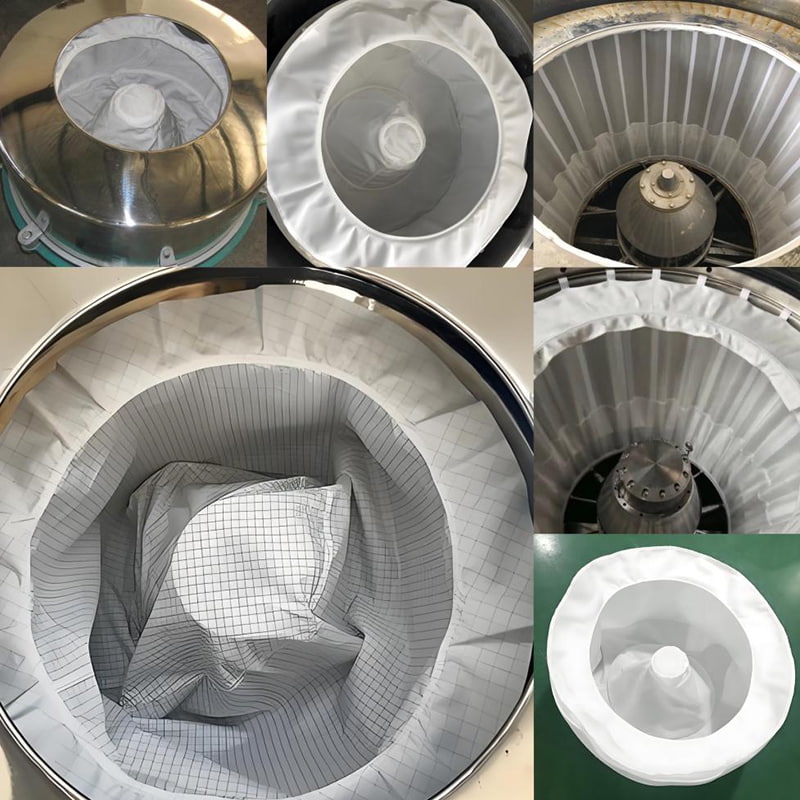

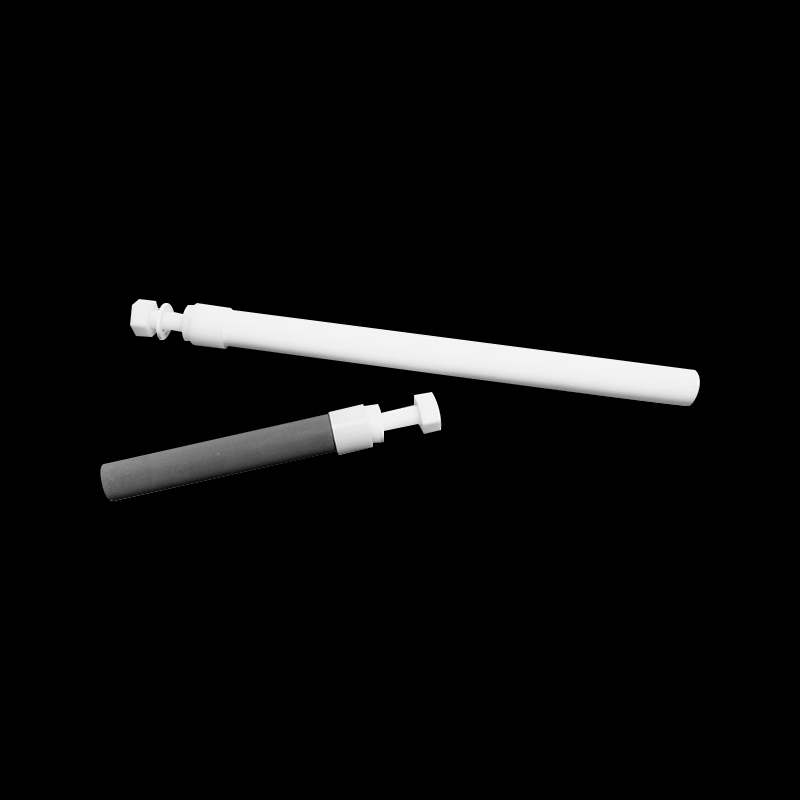

● Filter media materials: metal sintering mesh, metal powder sintering mesh, filter cloth

● Filtration accuracy: 3um-500um

● Seal form: double-face mechanical seal, packing seal

● The distance between blade and cylinder wall: 8-10 mm on one side

● Distance between blade and base plate: 8-10 mm

● Flatness of bottom plate: ± 1mm/m2

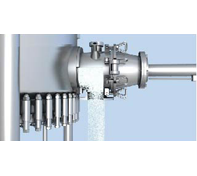

Working Process

|

|

|

|

| Filtration Stage | Washing Stage | Drying Stage | Unloading Stage |

Product Product Featuress

● The equipment is designed and assembled in strict accordance with the requirements of GMP and FDA fully in line with the requirements of drug production process, and the system is safe, stable and reliable;

● Completely closed filtration, no leakage and no environmental pollution.

● Operate under pressure or vacuum to realize solid-liquid separation. During filtration, the filter cake is evenly distributed and the solid-liquid separation effect is good.

● The lifting and lowering of the stirring system is controlled by hydraulic pressure. The space for slag holding is maximized during filtration. The lifting and stirring of agitator blades make the filter cake and cleaning solution fully mixed during cleaning, and the filter cake is fully washed; the time of drying is greatly reduced and the efficiency is improved.

● Hydraulic control of slag discharge valve, automatic scraping and discharging of slag system, reducing labor intensity.

● It is especially suitable for filtration occasions with large solid content, liquid phase and solid phase are recycled respectively.

● The corrosion-resistant three-in-one system made of special materials can adapt to a variety of corrosion-resistant media.

● The whole process can be carried out under the protection of inert gas, which is safe and reliable.

Technical Parameter

| Equipment Model | Cylinder diameter(mm) | Filtration Area(m) | Nominal Volume (m³) | Cake Thickness(mm) | Blade Lifting Height(mm) | Motor Power(KW) | Net Weight(KG) | Total Height(mm) | |||

| CJRH-400 | 400 | 0.125 | 0.07 | 120 | 150 | 0.55 | 860 | 2550 | |||

| CJRH-500 | 500 | 0.19 | 0.15 | 140 | 160 | 2.2 | 1500 | 3000 | |||

| CJRH-600 | 600 | 0.28 | 0.22 | 140 | 200 | 2.2 | 1700 | 3300 | |||

| CJRH-800 | 800 | 0.5 | 0.46 | 200 | 220 | 3 | 2250 | 3500 | |||

| CJRH-1000 | 1000 | 0.8 | 0.95 | 220 | 250 | 5.5 | 3500 | 3800 | |||

| CJRH-1200 | 1200 | 1 | 1.2 | 250 | 300 | 7.5 | 4900 | 4000 | |||

| CJRH-1400 | 1400 | 1.5 | 1.9 | 300 | 350 | 11 | 6500 | 4500 | |||

| CJRH-1600 | 1600 | 2 | 2.59 | 300 | 350 | 15 | 7500 | 4500 | |||

| CJRH-1800 | 1800 | 2.5 | 3.2 | 350 | 400 | 15 | 10000 | 4700 | |||

| CJRH-2000 | 2000 | 3 | 4.5 | 400 | 450 | 18.5 | 11700 | 5100 | |||

| CJRH-2300 | 2300 | 4 | 6.4 | 400 | 450 | 18.5 | 12800 | 5200 | |||

| CJRH-2600 | 2600 | 5.3 | 9 | 400 | 500 | 22 | 16500 | 5300 | |||

| CJRH-2800 | 2800 | 6 | 10.8 | 450 | 500 | 22 | 18650 | 5500 | |||

| CJRH-3000 | 3000 | 7 | 14 | 450 | 550 | 37 | 21230 | 5700 | |||

Note: the lifting stroke of mixing part can be designed according to user's requirements; other technical specifications can be designed according to user's process requirements. Shanghai ciie Environmental Protection Technology Co., Ltd.

About Cijie

Rugao Cijie Environmental Technology Co.,Ltd. is Three-In-One Multifunction Filter Manufacturer and Multifunction Filter Supplier. We are also a filtration company in China. It focuses on precision filtration, self-cleaning filtration, and sewage treatment equipment, and is committed to providing comprehensive professional filtration support for customers. The core technology team of Cijie has rich industry filtration experience, strong design and research ability, comprehensive use of comprehensive filtration products, and integration of global Into filter technology and product resources, to provide a one-stop solution.

With advanced technical strength and efficient service, we have established close cooperation with several well-known international brands, with a strong competitive advantage, to provide reliable protection for customer cooperation.

Shanghai Cijie filtration products are widely used in the petrochemical industry, sewage treatment, fine chemical industry, pharmacy, food and beverage, automobile industry, coating, papermaking, and other fields.

Shanghai Cijie Environmental Technology Co., Ltd. takes the principle of "science and technology leading, quality excellence" as the principle, and "serves users and returns to nature" as its purpose. It provides high-quality services for customers. The company has independent import and export operation rights and facilitates customer service at home and abroad. We also offer wholesale filtration, washing and drying 3 in 1 Multifunction Filter

Leave a Message

Latest news and exhibitions

-

12 Dec, 2025

12 Dec, 2025What is the relationship between Filter Bag surface area and dirt holding capacity?

The Direct and Critical Link: Filter Bag Surface Area to Dirt Holding Capacity The relationship between a Filter Bag's surface area and its dirt holding capacity is fundamental, direct, and non-linea...

Read more -

05 Dec, 2025

05 Dec, 2025Understanding Filtration Precision: What Particle Size Can the Liquid Multi-Core Filter Remove?

In the world of liquid filtration, the question of particle size removal sits at the very core of a system’s purpose and performance. For engineers, facility managers, and procurement specialists eval...

Read more -

21 Nov, 2025

21 Nov, 2025What is the Difference Between a Pleated and a Non-Pleated Filter Element?

In many industrial systems, filtration plays a crucial role in keeping equipment running reliably, protecting sensitive components, and maintaining consistent product quality. At the center of any fil...

Read more

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt