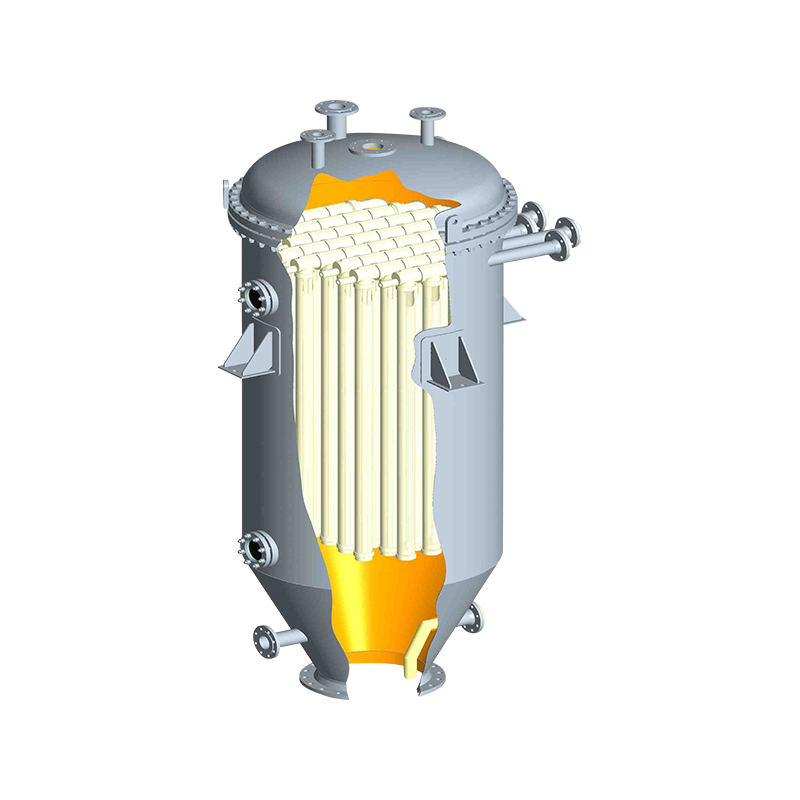

Designing an automatic candle filter for high-temperature applications involves several specific considerations to ensure efficiency, safety, and longevity. Here are some key factors to keep in mind:

Material Selection

High-Temperature Resistant Materials: The filter components should be made from materials that can withstand elevated temperatures without degrading. Common choices include stainless steel (like 316L), Inconel, or specialized ceramics.

Filter Media: The filter media itself must also be capable of handling high temperatures. Materials such as ceramic or metal mesh filters can be suitable, depending on the specific application and the type of contaminants being filtered.

Sealing and Gasketing

Thermal Expansion: High temperatures can cause materials to expand, leading to potential leaks. Ensure that seals and gaskets are made from high-temperature resistant materials, and consider designs that accommodate thermal expansion.

Integrity of Seal: The design should ensure that the seals maintain their integrity under high temperatures to prevent bypassing of unfiltered fluids.

Flow Dynamics

Viscosity Changes: At high temperatures, the viscosity of fluids can change significantly. The design must account for these changes to maintain optimal flow rates and prevent clogging.

Backpressure Management: High-temperature operations can lead to increased backpressure. The design should include features to manage and minimize backpressure to avoid damage to the filter and connected systems.

Automated Cleaning Mechanisms

Efficiency of Cleaning: Automatic cleaning systems, like backwashing or sonic cleaning, should be designed to operate effectively at elevated temperatures. Consider the thermal effects on the cleaning mechanism and ensure that it can handle the conditions without failure.

Control Systems: The automation controls should incorporate temperature sensors to adjust cleaning cycles based on the operating conditions and filter performance.

Safety Considerations

Pressure Relief Systems: High temperatures can lead to pressure build-up. Incorporate safety features such as pressure relief valves to prevent catastrophic failures.

Material Safety Standards: Ensure that all materials comply with relevant safety standards for high-temperature operations, as well as any industry-specific regulations.

Maintenance Accessibility

Ease of Maintenance: Design the filter for easy access during maintenance and replacement of filter media. High-temperature environments may require more frequent checks and replacements, so consider the ease of disassembly in your design.

Indicator Systems: Implement visual or electronic indicators for monitoring filter status, clogging, and temperature, allowing for proactive maintenance.

Designing an automatic candle filter for high-temperature applications requires a careful balance of material selection, sealing integrity, and flow dynamics, along with robust automation and safety features. By considering these aspects, engineers can create a reliable and efficient filtering system capable of operating effectively in demanding environments.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt